Die Casting Mould ( 33 )

Die Casting Mould ( 33 )

Die Casting Parts ( 338 )

Die Casting Parts ( 338 )- Aluminum Die Casting Parts ( 283 )

- Zinc Die Casting Parts ( 35 )

- Magnesium Die Casting Parts ( 11 )

- Copper alloy die casting parts ( 9 )

Aluminum Sand Casting Part ( 19 )

Aluminum Sand Casting Part ( 19 )

Steel Casting Part ( 33 )

Steel Casting Part ( 33 )

Machining parts ( 73 )

Machining parts ( 73 )

Metal Stamping Part ( 59 )

Metal Stamping Part ( 59 )

LED Lights ( 33 )

LED Lights ( 33 )

Repeater Case ( 23 )

Repeater Case ( 23 )

- Contact Person: Mr. General Ma

- View Contact Details

Scan to visit

Scan to visit- Aluminum Die-casting Water Pump Parts

- OEM Die Casting Water Pump Products

- Precision Aluminum Die Casting Pump Parts

- Die Casting Parts For Water Pump

- Aluminum OEM Die Casting Yacht Parts

- Aluminum OEM Die Casting Yacht Products

- OEM Aluminum Die Cast Yacht Parts

- OEM Aluminum Die-casting Yacht Parts

- Precision Aluminum Die-casting Yacht Products

- Customized Aluminum Die-cast Yacht Parts

- Aluminum High-pressure Casting Yacht Parts

- Aluminum OEM High-pressure Yacht Products

- Precision Aluminum Injection Yacht Parts

- Customized Aluminum Die Casting Yacht Maker

- Professional Aluminum Die-casting Yacht Spare Parts

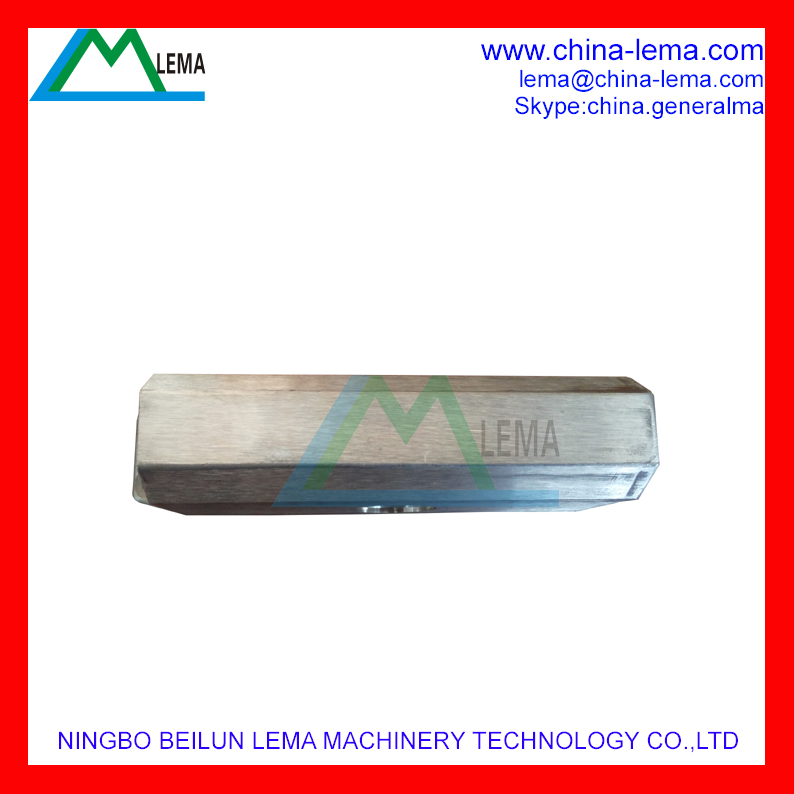

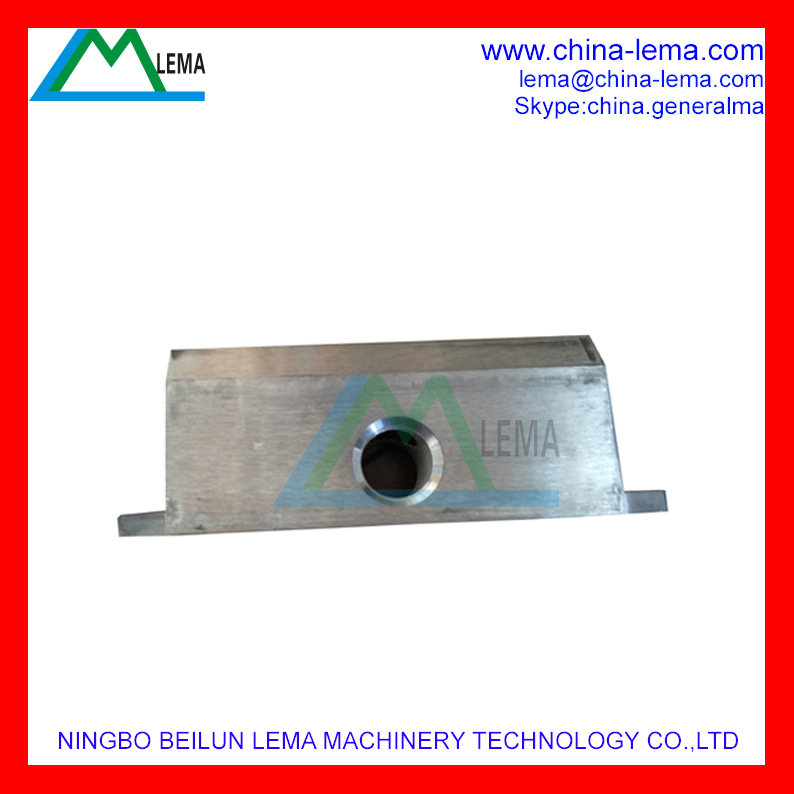

Aluminum die casting hydraulic automatic door closer

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Incoterm: | FOB,CIF,CIP |

| Min. Order: | 1 Piece/Pieces |

- Mr. General Ma

Basic Info

Model No.: LM-DL-001

Brand: LEMA

Material: Aluminum Alloy

Type: Anchor Point Of 90° Or No Anchor Point Of 180°

Installation Type: Doorframe

Function: Buffered

Standard: European Standard

Remote Control: Without Remote Control

Door Width: 1000mm

Door Weight: 25~45Kg

Usage: Market

Color: Silver

Product Name: Hydraulic Automatic Door Closer

Shape: Round Or Hydraulic

Max Door Weight: 25-45kg, 45-60kg, 60-80kg

Maximum Door Width: 500-2000mm

Door Closer Weight: 1-2.5kg

Finish: Powder Coating

Application: Office Door, Fire Door And Others

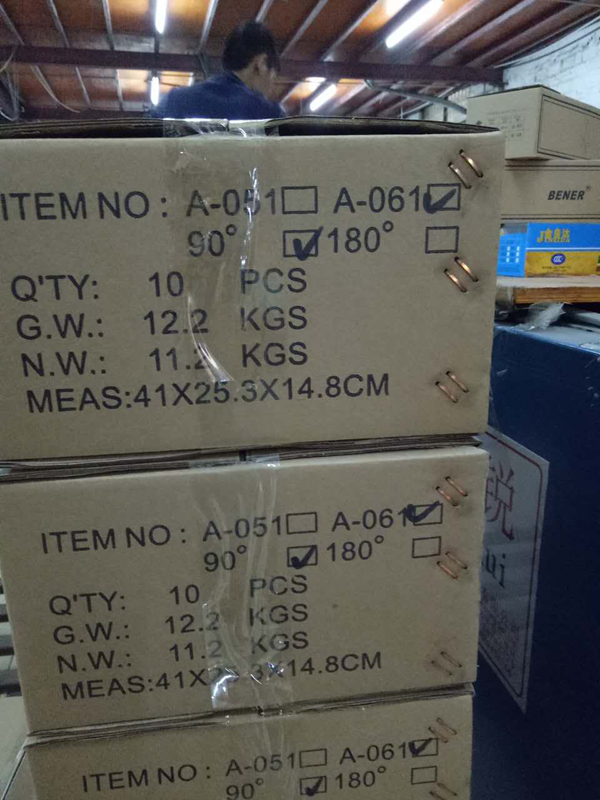

Packing: 1 Pc/small Box, 10 Pcs/carton

Additional Info

Packaging: 10 pcs/carton, wooden pallet

Productivity: 20000 pcs/month

Transportation: Ocean

Place of Origin: Zhejiang, China

Supply Ability: 5000

Certificate: CCC, ISO

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF,CIP

Product Description

Aluminum die casting hydraulic automatic door closer

- Product description

Operation principle for hydraulic automatic door closer:

Automatic door closing device, the working principle is when the door is opened, door body femoral artery connecting rod to act and make gear rolling drive rack piston move to the right. Spring was tightening on the right plunger in the process of hydraulic oil in the compression cavity of right. A one-way valve ball valve on the left side of the plunger is opened under the action of the oil pressure, and the hydraulic oil in the right cavity flows into the left cavity through a one-way valve. When after the completion of the opening process, because the spring in the open process by the austerity, the elastic potential energy of the savings were released, will push the piston to the left femoral artery and gear and door closers connecting rod rolling, to keep the door closed. In the spring to release process, because the door is the left chamber of the hydraulic oil by the compressed, the check valve is closed, hydraulic oil only through the gap between the shell and the plunger outflow, and through the hole in the plunger and two with save the spool flow back into the right chamber. Closed door varieties can be divided into: exterior and embedded in the top of the door closed, embedded door closed device, the bottom of the door behind closed doors (spring), vertical closed (built in vertical door closers) and other types of door closers.

Specification introduction for hydraulic door closer:

- The max width of door is 500-1000mm, suitable for door weight of 25-45kg, distance is 126mm*19mm

- The max width of door is 600-1200mm, suitable for door weight of 45-60kg, distance is 162mm*19mm

- The max width of door is 1000-2000mm, suitable for door weight of 60-80kg, distance is 229mm*19mm

- All types with a function of stopping at anchor point of 90°or no anchor point of 180 °

Detail pictures for automatic door closer:

Door closer accessories:

Customized Silk-screen logo:

- Packaging and shipping

- Company information

NINGBO BEILUN LEMA MACHINERY TECHNOLOGY CO., LTD is a companyspecialized in designing and manufacturing various kinds of moulds, aluminum die casting parts, zinc alloy die casting parts, aluminum gravity casting parts, aluminum sand casting parts, stainless steel casting parts, precision machining parts and metal stamping parts. The company mainly supply to automobile parts, motorbike parts, railway parts, communication parts and light parts for my customers. The most of parts are export to occident countries.

- Questions and Answer:

Q: How many years of experiences about your company?

A: We have 10 years experiences

Q: What kind of the materials and product do you provided?

A: We have aluminum, aluminum alloy, zinc, zinc alloy, magenesium and other materials, we provided Die Casting Mould, die casting part, sand casting, gravity casting, CNC Machining Part and so on.

Q: How long will delivery?

A: General within 25 days

Q: What's the advantage of your company?

A: We have advanced equipment and strict quality inspection

If you interested in our product please send inquiry to us!

We look forward to hearing from you!

Product Categories : Die Casting Parts > Aluminum Die Casting Parts