Die Casting Mould ( 33 )

Die Casting Mould ( 33 )

Die Casting Parts ( 338 )

Die Casting Parts ( 338 )- Aluminum Die Casting Parts ( 283 )

- Zinc Die Casting Parts ( 35 )

- Magnesium Die Casting Parts ( 11 )

- Copper alloy die casting parts ( 9 )

Aluminum Sand Casting Part ( 19 )

Aluminum Sand Casting Part ( 19 )

Steel Casting Part ( 33 )

Steel Casting Part ( 33 )

Machining parts ( 73 )

Machining parts ( 73 )

Metal Stamping Part ( 59 )

Metal Stamping Part ( 59 )

LED Lights ( 33 )

LED Lights ( 33 )

Repeater Case ( 23 )

Repeater Case ( 23 )

- Contact Person: Mr. General Ma

- View Contact Details

Scan to visit

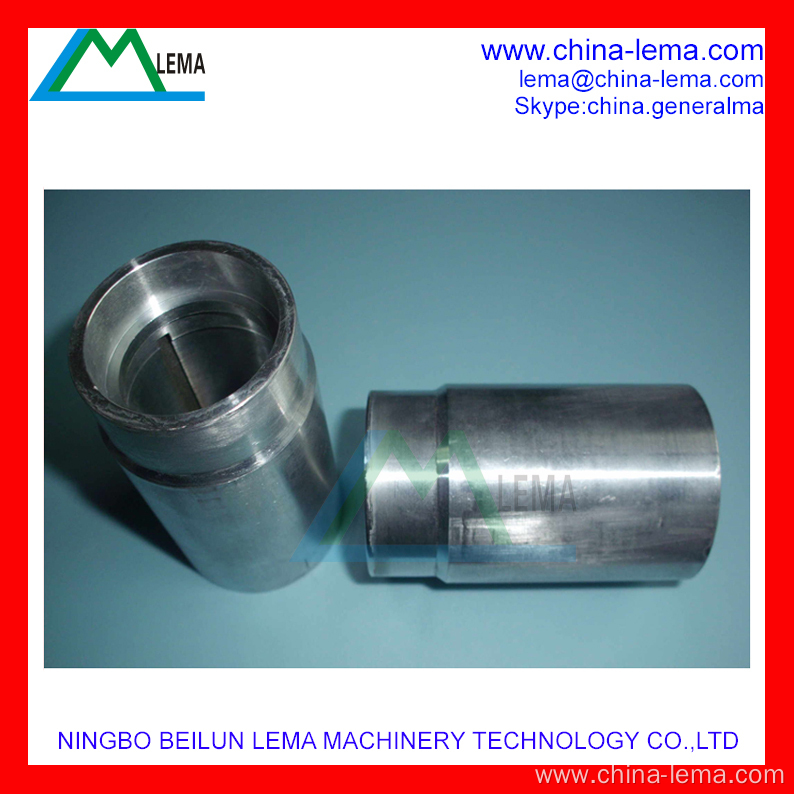

Scan to visit- OEM High-Precision Axis Machining Part

- Low Price Aluminum Filter Machining Part

- Aluminum CNC Housing Machining Part

- Precision Aluminum Body Machining Parts

- Aluminum ADC12 CNC Machining Part

- Aluminum Threaded Turning Machining Part

- OEM Precision Aluminum A380 Machining Part

- OEM Flange Turning Machining Part

- Stainless Steel Round Head Machining Part

- Aluminum CNC Turning machining Maker

- Aluminum OEM Turning machining Producer

- Ningbo CNC OEM Machining Parts

- Brass CNC Turning Machining Part

- Aluminum OEM Housing Machining Maker

- Aluminum Precision CNC Housing Machining Producer

Durable Zinc-alloy Machining Part

| Unit Price: | 3~5 |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 5000 Piece/Pieces |

- Mr. General Ma

Basic Info

Model No.: LM-15G030

Brand: LEMA

Additional Info

Packaging: Wooden box

Productivity: 500pcs/day

Place of Origin: Ningbo

Supply Ability: 15000pcs/month

Certificate: SGS

Incoterm: FOB

Product Description

Machining

One of the main reasons for specifying a diecasting, particularly a zinc alloy diecasting is to avoid the finish machining needed with most other forming processes. However finish machining of zinc alloy diecastings is still required on occasions, particularly to produce features that are not readily cast without sliding cores in the die. For parts produced in high quantities the cost of extra moving die elements is easily justified but for lower volume parts it is sometimes more cost effective to machine the casting. Zinc diecasting alloys are economical to machine and high quality finishes are readily obtained. Reference should be made to the [Machining" section of this document for ideal parameters for the range of machining processes. Probably the most important thing to remember when machining zinc is the prevention of heat build up at the cutting edge, by maintaining tool sharpness and applying adequate coolant.

Compared to other diecasting alloys, zinc alloys machine faster and with less tool wear than aluminium alloys and without the fire risk involved with magnesium diecastings.

Compared to materials formed by other processes, zinc alloy diecastings have the advantage that accurate datum surfaces can be provided for clamping and hence it is generally easier to achieve accuracy in the machining operation.

One machining operation that is commonly performed on zinc alloy diecastings is tapping of holes to produce female threads. Most frequently the hole is produced by a core in the die rather than by drilling after casting. Unless minimising torque relaxation of the fastener screwed into the threaded hole is critical, it is usually better to use fluteless thread forming taps. These produce no swarf and hence avoid the necessity of a process stage to ensure its elimination from the diecasting. In fact the avoidance of swarf by avoiding machining is another plus for zinc alloy diecastings. Swarf remaining on components of electrical, electronic, pneumatic and hydraulic components is a common cause of product failure.

The kinds of material of Steel machined Mobile parking lot part:bar stock of steel 1025, 1045;

The precision of the machining steel Mobile parking elevator: H7;

Machined of machining: Milling machine and CNC machining;

Smoothness of surface after Steel alloy machined mobile parking part: Ra1.6;

Step of working out process regulations:

1) Calculating annual production program, determine the type of manufacture.

2) Analysis part drawing and the product assembly drawing.

3) Select blank.

4) Formulation process route.

5) Determine the machining allowance of each process, calculating the dimension and tolerance.

6) Identify the equipment used in each process and cutting tool, jig, measuring tools and auxiliary tools.

7) Determine the cutting dosage and man-hour quota.

8) Determine the main process of technical requirements and test methods.

9) Fill in the process documents.

Machining Steel Mobile Parking Elevator production equipment and management system

CNC machining center: 8 sets;

CNC lathe machine: 16 Guangzhou Machines;

Work days of one week: From Monday to Saturday;

Shift work: 2 shift per day;

Working hours: From AM 8:00 to PM 5:00;

2D and 3D drawing Software: AutoCAD, UG, Pro/E, SolidWorks 2013;

QC control: New type NANO CMM, FPI M5000 desktop metal analyzer, Easson projector, Mechanical properties tester.

Steel machining Mobile parking space part equipment and QC control equipment

Product Categories : Machining parts