Die Casting Mould ( 33 )

Die Casting Mould ( 33 )

Die Casting Parts ( 338 )

Die Casting Parts ( 338 )- Aluminum Die Casting Parts ( 283 )

- Zinc Die Casting Parts ( 35 )

- Magnesium Die Casting Parts ( 11 )

- Copper alloy die casting parts ( 9 )

Aluminum Sand Casting Part ( 19 )

Aluminum Sand Casting Part ( 19 )

Steel Casting Part ( 33 )

Steel Casting Part ( 33 )

Machining parts ( 73 )

Machining parts ( 73 )

Metal Stamping Part ( 59 )

Metal Stamping Part ( 59 )

LED Lights ( 33 )

LED Lights ( 33 )

Repeater Case ( 23 )

Repeater Case ( 23 )

- Contact Person: Mr. General Ma

- View Contact Details

Scan to visit

Scan to visit- Electric iron die casting tooling

- Diesel duplex generator die casting mold

- Aluminum Die Casting Die

- Aluminum High Pressure Casting Mould

- Zinc Die Casting Mould

- Zamak die casting mould

- Aluminum high pressure casting tooling

- Magnesium Vacuum Die Casting Mould

- High Quality Aluminum Vacuum Die-casting Mould

- Aluminum die casting dies

- Magnesium alloy die casting mould

- High presion 5 axis machining die casting die

- Jaguar land rover mould

- Land rover auto car tooling

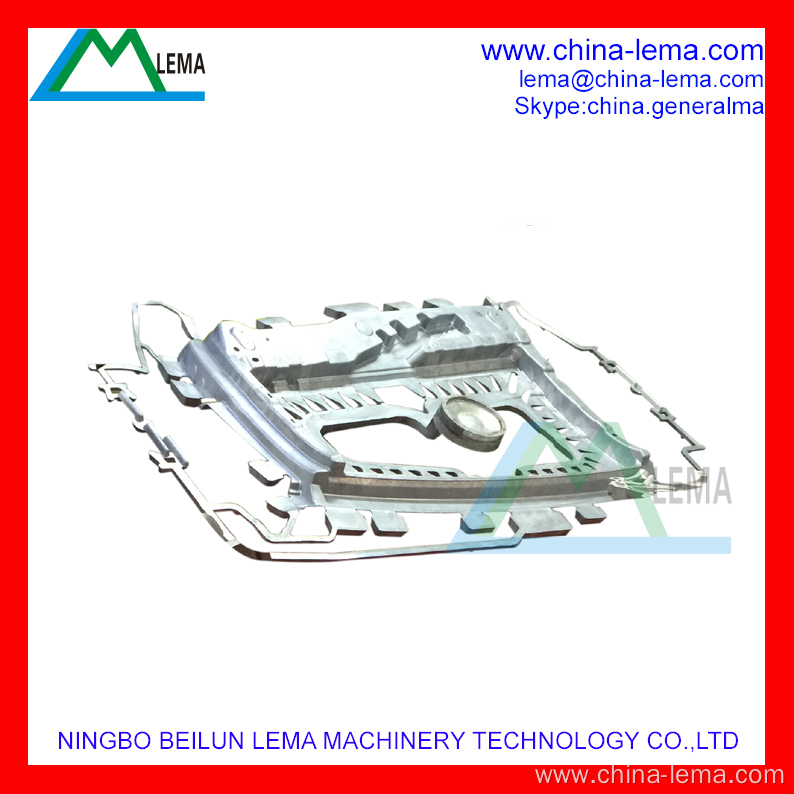

- Tesla Motors door mould

Tesla Motors door mould

| Unit Price: | 50000~60000 USD |

|---|---|

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

- Mr. General Ma

Basic Info

Model No.: LM-15A031

Brand: LEMA

Additional Info

Packaging: Wooden box

Productivity: 120sets/year

Transportation: Ocean,Land,Air

Place of Origin: Ningbo

Supply Ability: 10sets/month

Payment Type: T/T,Western Union

Incoterm: FOB

Product Description

Tesla Motors door mould manufactured in our factory by 5-axis CNC machining center.

Introduction of high precision die-casting tooling

Basic Introduction

Die casting, die casting machine, die casting materials are three main factors for die casting production. The die casting technology is the synthetically use of these three elements organically, make can steadily and rhythmically to efficiently produce appearance and inner quality, size meet the requirements of the drawings and high quality casting process.

Die casting alloy is mainly used by non-ferrous alloy, as for the black metal (steel, iron, etc.) due to problems such as mould material, use fewer. And aluminum alloy is used more widely in the non-ferrous alloy, then the zinc alloy.

The domestic current situation of the high precision tooling

Die Casting Mould industry has developed rapidly in our country, the total output growth significantly, domestic die casting mold production after the United States, has become the second in the world, become the veritable die-casting superpower. It can have such achievement because of our country with unique broad market advantages and relatively cheap labor force. Depend on very obvious price in the international trade market, we produced the die casting mould which occupies a bigger superiority, according to the situation, in the future Chinese die casting industry development prospects are very broad.

The designing of Tesla Motors die casting mould

1, According to the materials, shape and precision product, analyze technology, decide of the process.

2, Confirm the location of product in the mold cavity. Analyze parting surface, overflow system and the gating system.

3, Design the various activities of the core are assembled and fixed method.

4, Design the core-pulling distance and force.

5, Design the ejection device.

6, Confirm the die casting machine, design the mould base and the cooling system.

7, Checking the mould size and die casting machine, drawing the process flowchart and component of die casting mold.

8, Design is complete.

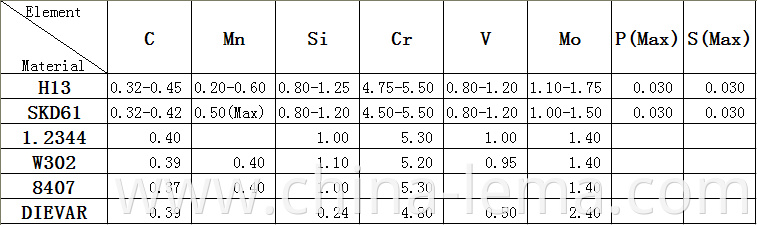

Auto car door mould material and materials and its properties

Material of Aluminum Die Casting Mould: H13, ASSAB DIEVAR, SKD61;

Mould base: #45 steel, standard mould base(LKM);

Hardness after treatment: RHC 48~52;

Standard Configuration: Cooling system;

Tolerance: 0.1mm;

Machining equipment: CNC gantry milling machine, middle-speed WEDM machine, slow-feeding EDM, die spotting machine;

Mould life: 50000 shots ~ 100000 shots;

Lead time of die casting mould: 40 days-60 days.

The Common mold material

The designing of Die casting door mould

1, According to the materials, shape and precision product, analyze technology, decide of the process.

2, Confirm the location of product in the mold cavity. Analyze parting surface, overflow system and the gating system.

3, Design the various activities of the core are assembled and fixed method.

4, Design the core-pulling distance and force.

5, Design the ejection device.

6, Confirm the die casting machine, design the mould base and the cooling system.

7,Checking the mould size and die casting machine, drawing the process flowchart and component of die casting mold.

8, Design is complete.

My factory magnesium die casting door mould production equipment and QC control

Product Categories : Die Casting Mould