Die Casting Mould ( 33 )

Die Casting Mould ( 33 )

Die Casting Parts ( 338 )

Die Casting Parts ( 338 )- Aluminum Die Casting Parts ( 283 )

- Zinc Die Casting Parts ( 35 )

- Magnesium Die Casting Parts ( 11 )

- Copper alloy die casting parts ( 9 )

Aluminum Sand Casting Part ( 19 )

Aluminum Sand Casting Part ( 19 )

Steel Casting Part ( 33 )

Steel Casting Part ( 33 )

Machining parts ( 73 )

Machining parts ( 73 )

Metal Stamping Part ( 59 )

Metal Stamping Part ( 59 )

LED Lights ( 33 )

LED Lights ( 33 )

Repeater Case ( 23 )

Repeater Case ( 23 )

- Contact Person: Mr. General Ma

- View Contact Details

Scan to visit

Scan to visit- Aluminum Foundry Casting Part

- Aluminum Alloy Sand Cast Part

- Al sand casting part

- Al alloy sand-cast part

- Aluminium Sand Casting Maker

- Aluminum sand casting air exhaust manifold

- Aluminium alloy sand casting part

- A356 sand casting part

- Aluminum alloy sand-cast product

- Aluminum sand casting bracket

- Foundry Casting Aluminum Pipeline Product

- Aluminum Bronze Sand Casting Fixture

- Customized Precision Cu Sand Casting

- Precision Ductile Iron Resin Sand Casting

- Precision Powder Coating Sand Casting Parts

Aluminium alloy sand casting part

| Unit Price: | 1~2 USD |

|---|---|

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | FOB |

| Min. Order: | 50 Piece/Pieces |

- Mr. General Ma

Basic Info

Model No.: LM-15E010

Brand: LEMA

Additional Info

Packaging: carton box and wooden box

Productivity: 5000pcs/month

Transportation: Ocean,Land,Air

Place of Origin: Ningbo

Supply Ability: 60000 pcs/year

Certificate: SGS

Payment Type: T/T,L/C,Western Union

Incoterm: FOB

Product Description

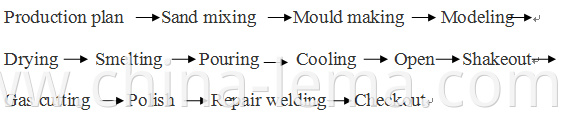

Aluminium alloy sand casting production technology process:

Common materials of aluminium alloy sand casting part:

The precision of the Aluminium alloy sand cast part: ±1mm~

Smoothness of surface of rough part: Ra6.4;

Shrinkage rate of Aluminium alloy sand casting part: 2%;

Material wastage rate: 7%;

General al sand casting machining allowance: 2mm~3mm;

Surface preparation methods: Sand blasted, Shot blasting, Powder coating, Painting, Plating, Electrophoresis, Polishing.

Advantages and disadvantages of Aluminium alloy send casting part:

Generally use wooden and aluminum mold, far cheaper than metal mold casting mould. The price advantage is particularly prominent in small batch and bulk production. But the production efficiency is low; Low dimension accuracy of castings, the surface is rough.

Our company's production equipment and management system

CNC machining center: 8 sets;

CNC lathe machine: 6 Guangzhou Machines and 7 Shenyang Machines;

Work days of one week: From Monday to Saturday;

Shift work: 2 shift per day;

Working hours: From AM 8:00 to PM 5:00;

2D and 3D drawing Software: AutoCAD, UG, Pro/E, SolidWorks 2013;

QC control: New type NANO CMM, FPI M5000 desktop metal analyzer, Easson projector, Mechanical properties tester.

The Aluminium sand casting maker's machining equipment and QC control

Product Categories : Aluminum Sand Casting Part